Using the 830B Digital Multimeter in the Home

by

James Bryant

A digital multimeter, sometimes known as a digital voltmeter or DVM (slightly inaccurately as it measures amps and ohms as well as volts), is an instrument which is used for making electrical and electronic measurements. There are many different types, with widely varying accuracies. The 830B is a very cheap and simple one, with an accuracy of about 1%, and a resolution of 0.05% of full scale. (This means that you can measure changes of voltage of one two thousandth of the maximum, but the actual accuracy of the measurement is only one hundredth of the maximum.)

The 830B is made by several manufacturers and sold under many brand names. It may be called the DT-830B, the M-830B or other varients on its number, and its case may be yellow (commonest), black, or even more exotic colours. It is available on eBay from China or Hong Kong for little more than £2/$3/€2.5 (buy on eBay US or eBay UK - the Euro price on eBay France was nearly three times as high when this article was written in 2011).

Despite its simplicity the 830B is very useful - it will measure voltages (both AC and DC), resistance, and DC current. Electrical and electronic engineers have innumerable uses for such a device, but in the average household there are three important uses - checking batteries and AC/DC power supplies ("Wall Warts"), checking fuses and light bulbs, and checking wires and cables for short-circuits and open circuits. It is easy to make such measurements and they can save hours of frustration. Every household should have one.

Fitting the Battery

Before using the meter it must be fitted with a small 9V battery. It is best to use an alkaline one as they have a longer life and are less likely to corrode. Such batteries are sometimes known as transistor radio batteries, or by the type numbers PP3, MN1604, 6LR61 or 6LF22. Unscrew the two small Philips screws in the back of the case and lever up the bottom of the case to fit the new battery - before replacing the back and the screws check that the fuse is OK as well.

The fuse should be mounted in a socket (see below for more detail) but the one in the picture has been soldered in place (it's a cheap meter) and sometimes there is not even a cartridge fuse - simply a length of very thin wire (≤0.05 mm dia) soldered where the cartridge should be.

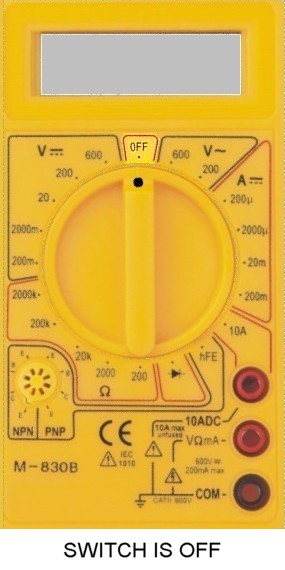

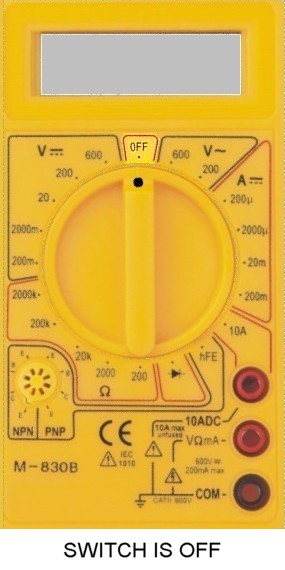

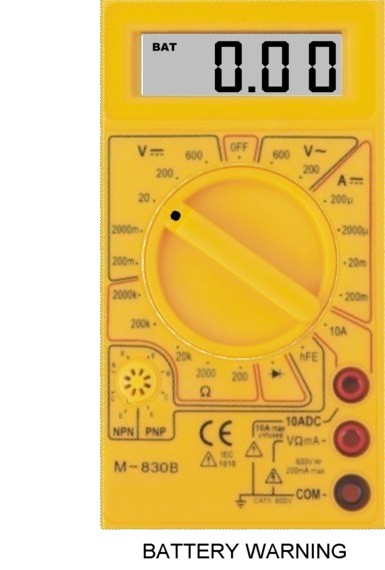

The battery will last for two or three years with occasional use, but only for about two to three weeks if the meter is left turned on[1] - so it should be turned off when it is not in use by rotating the switch so that it points upwards.

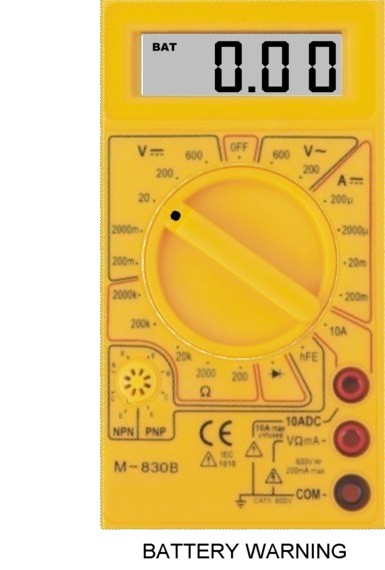

Note that when the meter is off there is no visible display - the screen is a uniform grey - and when the battery needs replacing (when its voltage has dropped to about 7 V) the warning BAT appears in the upper left-hand side of the screen in addition to the normal display while the meter is turned on.

[1] The current consumption is about 1 mA and a good alkaline PP3 battery has a capacity of about 500-600 mAh.

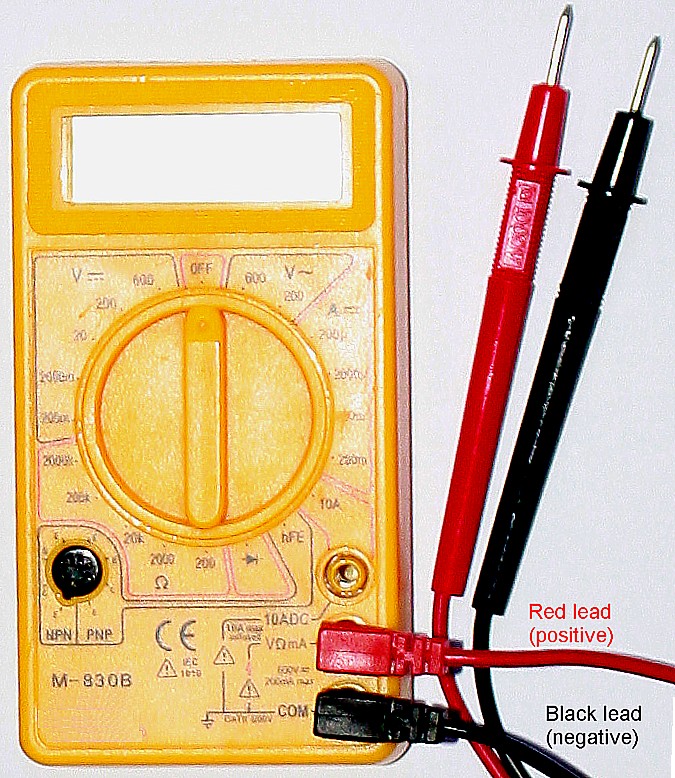

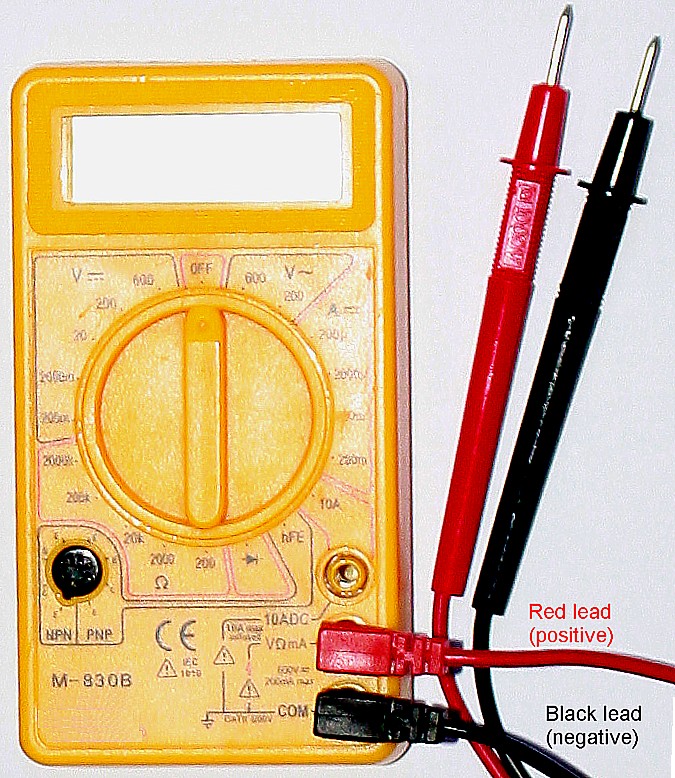

Fitting the Leads

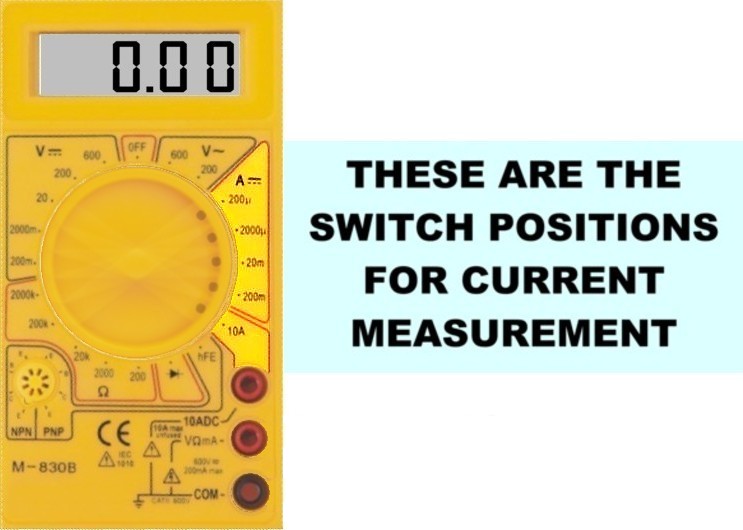

In use the black lead is plugged into the lowest of the three sockets (unsurprisingly the black one) and the red lead into the centre socket (the lower of the two red sockets). The red lead should never be plugged into the other red socket except to measure large DC currents (up to 10 amps). It is possible (though unlikely) that incorrect connection of the red lead may cause damage to batteries being checked or to the meter itself.

The Internal Fuse

It is also possible to damage the meter if it is switched to current measurement while it is connected to a battery or other voltage source - this will often blow the internal fuse. If this happens the meter will still have a display, but it will not work - it will simply show zeros (or over-range on the resistance ranges) no matter what is connected to it. In such an eventuality the back must be removed and the fuse replaced with a new one. See the diagram in the "Fitting the Battery" section above.

The correct cartridge fuse is a 250 mA fast blow type - 20 mm × 5 mm Ø. Sadly, the manufacturers often fit larger (1A or 3A) fuses in new meters because they are cheaper, but 250 mA is the correct rating. Also (see above) the fuse may be soldered in place instead of being mounted in a fuse mount, or even be a length of very thin (~0.05 mm dia) fuse wire, again soldered in place, may be used instead of a cartridge fuse.

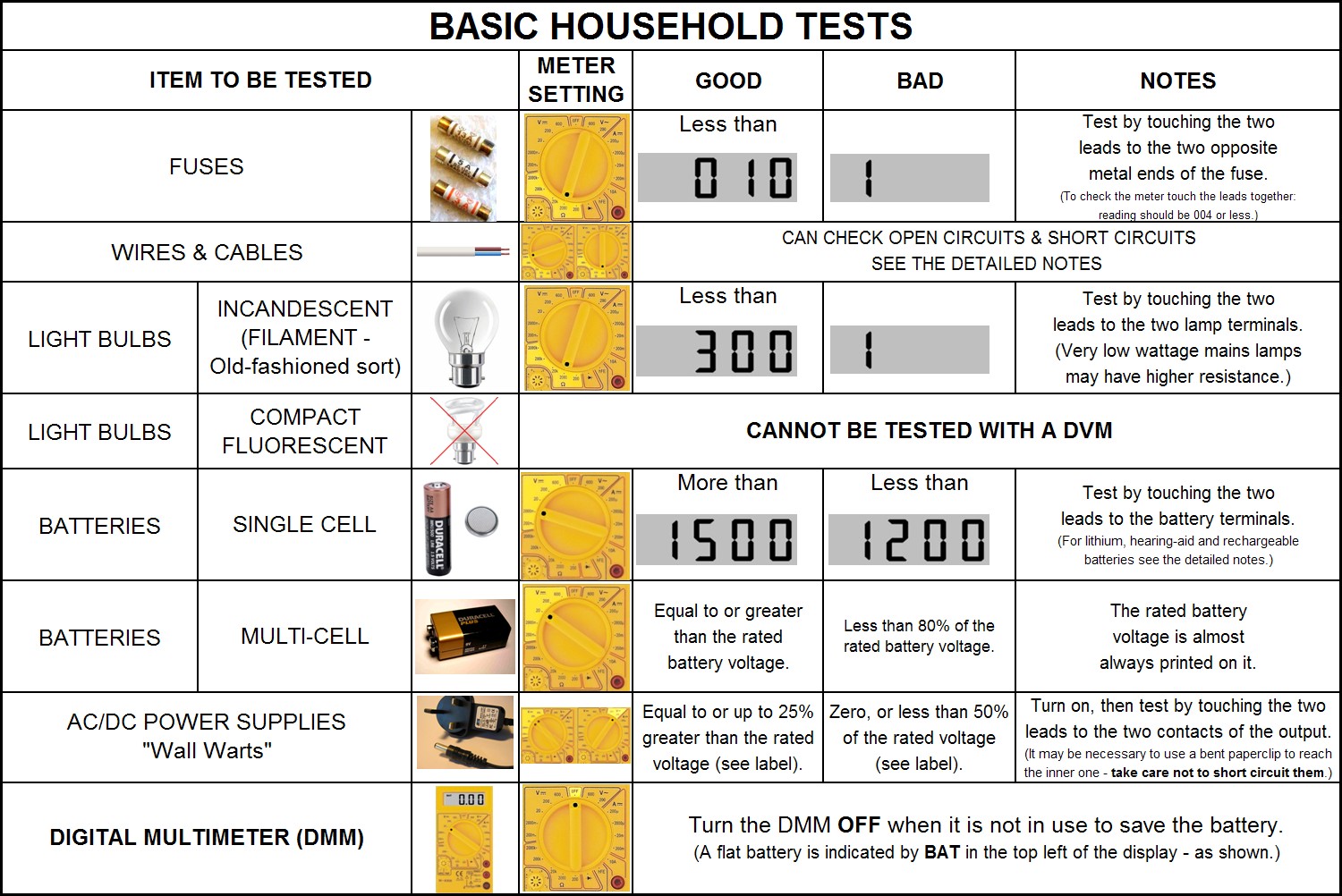

HOUSEHOLD MEASUREMENTS

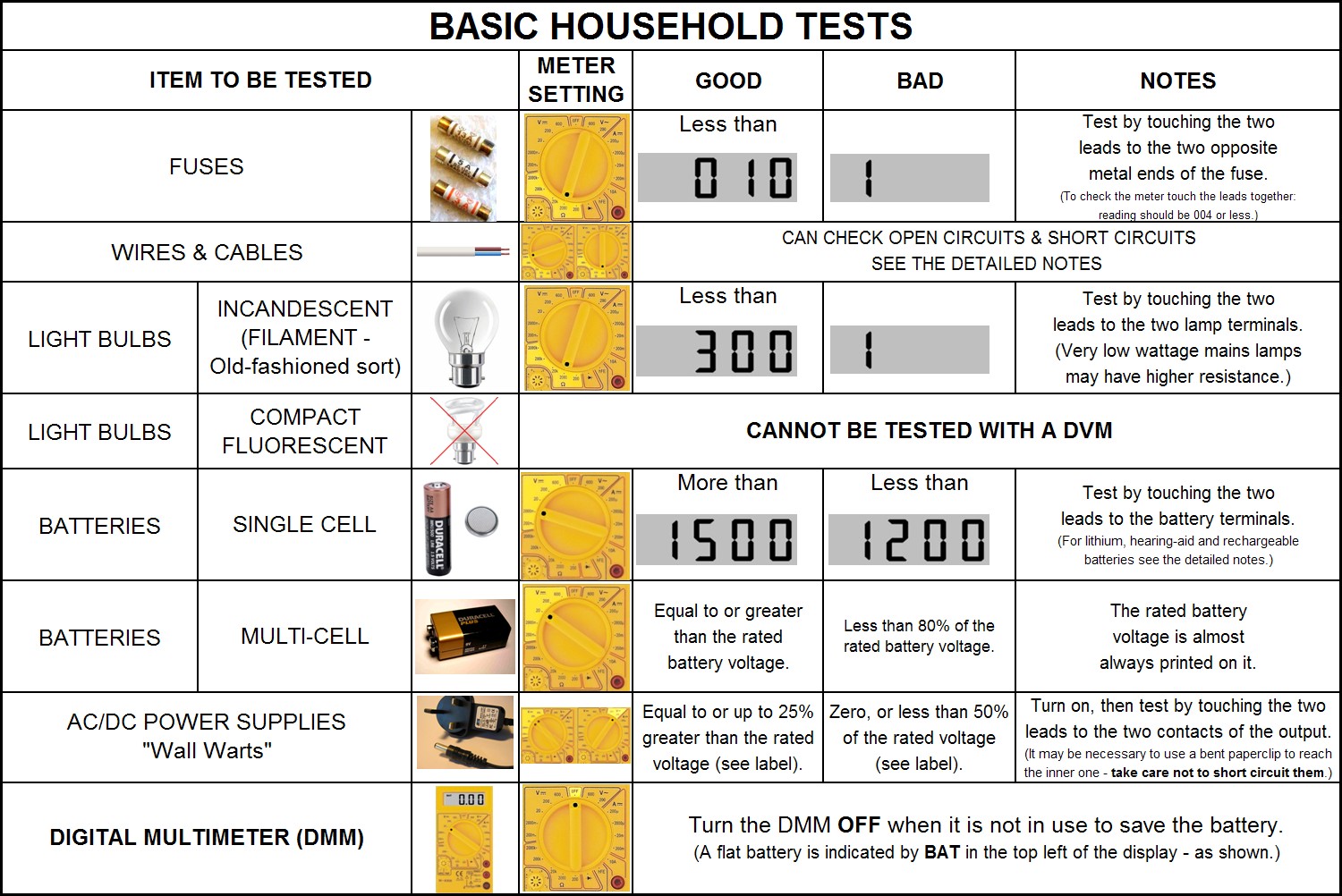

Fuses

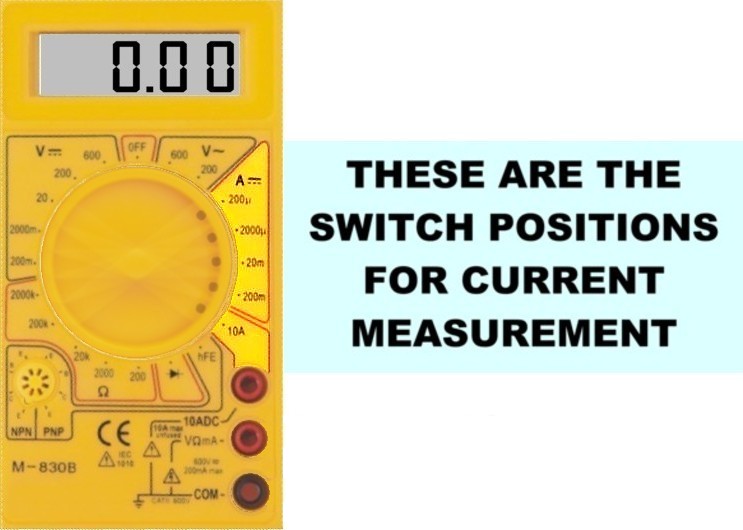

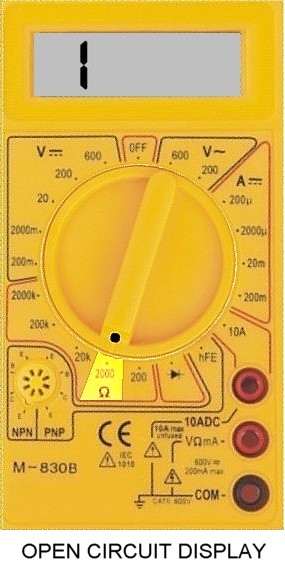

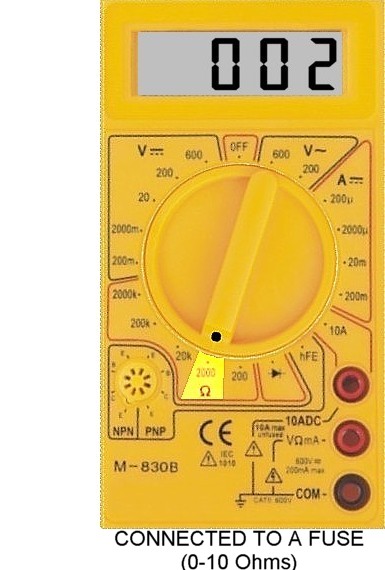

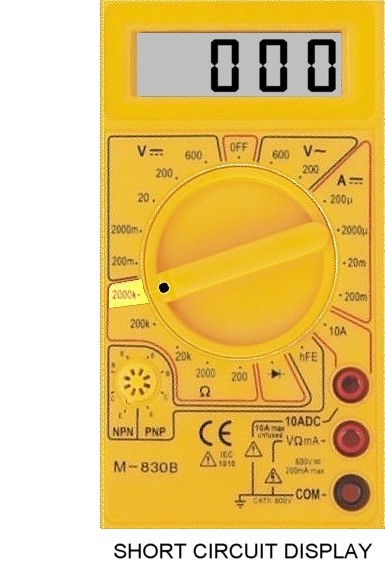

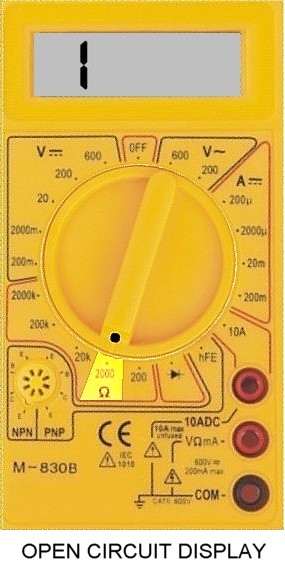

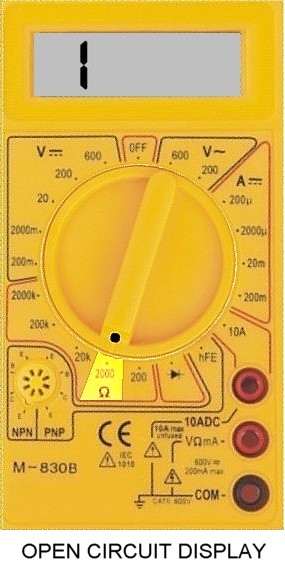

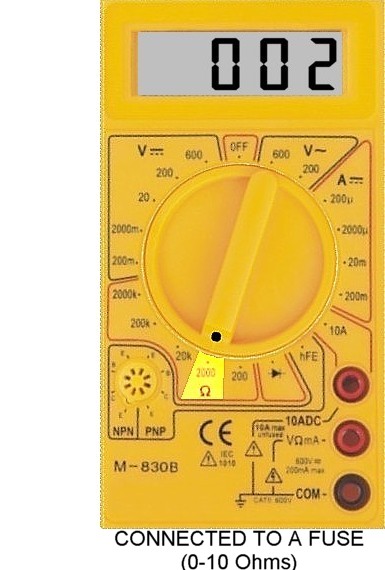

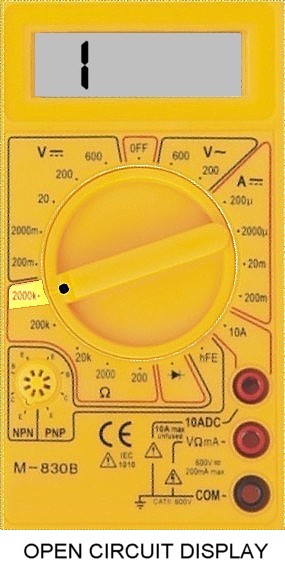

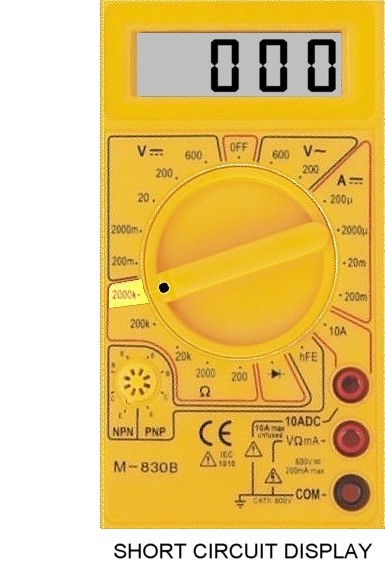

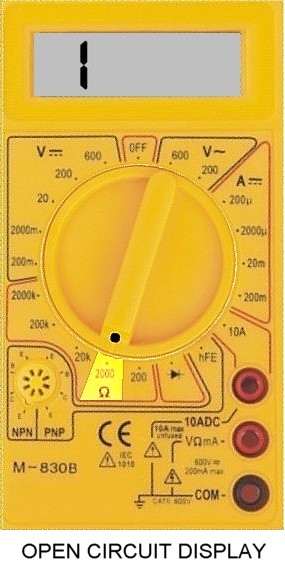

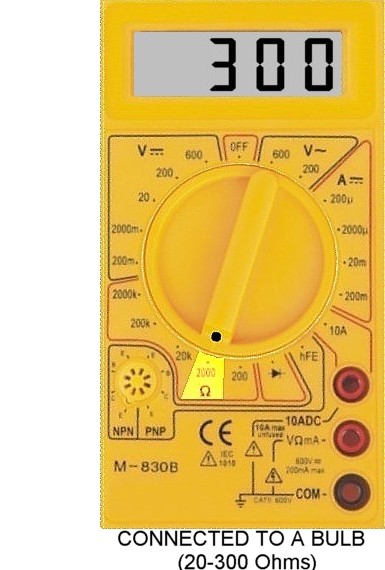

Use your DVM to check if a fuse is blown. Set the DVM to its 2000 Ω (2000 Ohm) range. When the leads are not connected to anything you should see an open-circuit display as shown. If the leads are touched together to test the meter you should see a display of between zero and 2 Ω, which is the resistance of the leads.

Now touch the leads to opposite ends of the fuse. If you see a resistance of between 0 and 10 Ω the fuse is good, if it is open circuit it is dead and should be replaced. (Throw it away at once - it is easy to keep a blown fuse and use it instead of a good one at some time in the future.) Before fitting a new fuse check that it is indeed a good one.

Wires & Cables

The DVM can be used to check if wires and cables are sound. They can fail in two ways - they may break internally, either at a connector or somewhere where they have been stressed, or they may develop a short-circuit (i.e. an unwanted connection) between wires which should not be connected to each other. The DVM can check for both problems but the wires must be isolated while they are tested - never check a wire or cable while it is connected to anything, in particular to any power source.

To check continuity (i.e. lack of internal breaks) set the DVM to its 2000 Ω (2000 Ohm) range and proceed in the same way as when you were testing a fuse. (See the meter diagrams for fuse testing.)

When the leads are not connected to anything you should see the open-circuit display and if the leads are touched together to test the meter you should see a display of between zero and 2 Ω, which is the resistance of the leads. Now touch the leads to opposite ends of the wire or cable. If you see a resistance of between 0 and 10 Ω it is good, if it is open circuit it is faulty.

Simple wires contain one conductor and are tested once. Many cables contain two or more conductors and the continuity of each one must be tested separately. If all of them are good you should then check the cable for short circuits.

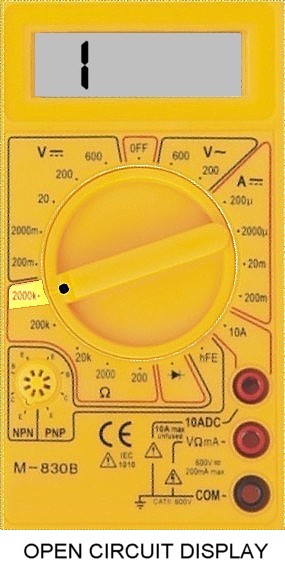

Set the DVM to its 2000 kΩ (2,000,000 Ohm or 2 MOhm) range. Again check correct operation - when the leads are not connected to anything you should see the open-circuit display and if the leads are touched together you should see a display of zero.

Now check for short-circuits. It is necessary to check for possible short circuits between every pair of wires in the cable - if there are only two or three wires this is easy, but if there are a larger number it is important to be methodical to ensure that no pair is overlooked. The best way is to join all the wires together electrically, then detach each wire in turn and check for a short circuit between it and all the rest. As each wire is checked it is left detached (it could be reconnected, but it is easier to verify that you have tested every wire by detaching them one at a time and leaving them detached - when there is only one wire left you're done).

If you find a short circuit[2] you should check if is in the cable itself or in a connector. It is sometimes possible to repair a short circuit in a connector (unless it is moulded onto the cable), but a cable with a short circuit, like a blown fuse, should be thrown away immediately.

[2] Sometimes if you are touching the ends of both test leads a little current may flow through your skin - this is quite harmless but in such a case you may not see the open circuit display, but a display of many hundreds of thousands of ohms. This is still a good indication that there is no short circuit.

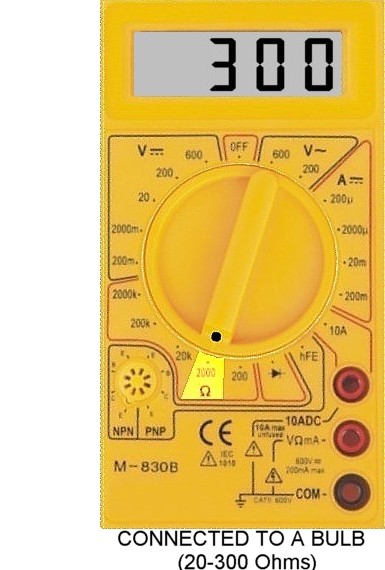

Light Bulbs

It is not possible to use the DVM to check modern LED or compact fluorescent light bulbs but you can use it to check if an old-fashioned filament (incandescent) light bulb has died. To do so set the DVM to its 2000 Ω (2000 Ohm) range as you do for testing a fuse. As with that test when the leads are not connected to anything you should see an open-circuit display and if the leads are touched together you should see a display of the lead resistance, between zero and 2Ω.

Now touch the leads to the contacts of the incandescent bulb. (Light bulb contacts are often dirty - to make sure that you make a good electrical connection to them when making this test use the point of the probe to go through any dirt or corrosion.) If you see a resistance of between 20 Ω and 300 Ω the bulb is good[3], if it is open circuit it is dead and should be replaced, if it is a short-circuit (2 Ω or less) the bulb is probably faulty and may blow a fuse if used - it should be checked in a light-holder where a blown fuse does not matter. As with a fuse, before fitting a new bulb do check that it is indeed a good one.

[3] These guidelines are necessarily imprecise - with very low power mains bulbs (<10 W) the resistance may exceed 300 Ω, with very high power, or low voltage, bulbs it may be under 20 Ω.

Batteries

One of the commonest reasons that a battery-powered device stops working is a dead battery. The meter allows you to check the battery when something stops working, and also to check the condition of a new battery before fitting it, since a small but appreciable percentage of new batteries are dead on arrival.

To measure the voltage of a battery turn the switch to DC Volts - the 2000 millivolt (2 volt) range for single cell batteries (except lithium ones - see below), or the 20 volt range for most multi-cell batteries. For the very few batteries with output voltage greater than 20 volts use the 200 volt range.

Then touch the probes on the ends of the leads to the connections of the battery. Ideally the positive lead should go to the positive battery terminal, and vice versa, but it does not really matter - if the leads are reversed the voltage reading is also reversed and the voltage will show as negative.

On the 2000 millivolt (2 volt) range the reading is in millivolts (thousandths of a volt) and there is no decimal point (the reading illustrated is 1546 mV which equals 1.546 V). The other ranges have a decimal point and show volts (except the 200m [200 mV] range which shows millivolts).

Replaceable (Non-Rechargeable or Primary) Batteries

Alkaline & Leclanché batteries

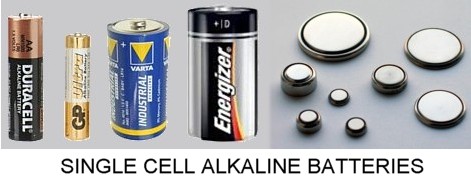

The common replaceable batteries for domestic battery-powered devices will be alkaline and the package should say "alkaline" somewhere on the package or the battery. Cheap batteries which do not say "alkaline" are probably the older Leclanché type, which work quite well but have shorter lives and are more likely to leak. Their voltages are the same as the alkaline ones.

A new single-cell alkaline battery should have a voltage between 1.5 and 1.65 volts (the reading will be between 1500 and 1650). A new battery with a voltage below 1.5 volts is suspect and may be expected to have a short life. If a device uses several single-cell batteries it is best to use a set of the same type and check that they all have similar (not necessarily exactly identical) voltages when they are installed.

Multi-cell alkaline batteries may have nominal voltages of 4.5 V, 6 V, 9 V, 12 V or even more. When new their voltages should be 4.5-5 V, 6-6.6 V, 9-10 V, or 12-13.2 V respectively.

As alkaline batteries are used their voltage drops gradually over their life. If you test alkaline batteries from a device which is not working and find that single cells have a voltage below 1.2 V, and below 3.6 V, 4.8 V, 7.2 V or 9.6 V respectively for 4.5 V, 6 V, 9 V, or 12 V batteries (in other words 80% of nominal), it is likely that the low battery is the cause of the problem and it should be replaced. Many devices will work at much lower battery voltages, possibly as low as 60% of nominal, but if a device fails to work and its battery is below 80% of nominal the battery should be replaced.

Button cells

Button cells are the small button shaped single-cell batteries (illustrated with the single-cell alkaline batteries above) which are often used in small, low-powered electronic devices. There are an enormous number of different sizes, which I shall not discuss, but four different types: alkaline, silver, zinc-air and lithium (there used to be mercury button cells as well but they are no longer manufactured as the materials involved are too toxic).

Silver and alkaline button cells

Both silver and alkaline button cells have initial voltages of 1.5 to 1.65 volts and the end of life is below 1.2 volts. The difference is that the voltage of the silver based cells remains fairly constant for most of their life and then drops abruptly, while alkaline button cells behave like any other alkaline cell and have a voltage which drops fairly steadily with use.

Zinc-air (hearing aid) button cells

Zinc-air button cells are used for hearing aids. Once the cell is opened to the air by removing the adhesive label from the cell they have a lifetime of only a few weeks, whether or not they are actually used. Their initial voltage is about 1.4 volts and end of life is just below 1 volt.

Lithium button cells and batteries

Lithium button cells (which almost always have type numbers CR××× or CR××××, where × is a numeral) have a much higher voltage. New lithium button cells have a voltage of 3 to 3.5 volts, and their end-of-life voltage is a little over 2 volts. If they are not used lithium cells have a very long shelf life - sometime as much as 15 years. Normal batteries (AA, AAA, PP3, etc.) are sometimes made with lithium technology because of this long life. Single cells will have a higher voltage (3-3.5 V) than the corresponding alkaline ones, but multi-cell batteries normally have the same voltages.

Rechargeable (Secondary) Batteries

Rechargeable alkaline batteries

Some alkaline batteries may be recharged with special chargers (note that they must be charged with chargers designed for alkaline batteries - chargers for NiCd or NiMH batteries are not suitable). Such batteries are labelled "Alkaline Rechargeable" or some near equivalent and have the same initial and end of life voltages as other alkaline cells (1.5-1.65 down to 1.1-1.2 volts) - the difference is that at the end of their life they may be recharged instead of being thrown away.

If you attempt to recharge non-rechargeable alkaline batteries you may find that they leak corrosive caustic potash, explode, or catch fire. It is wiser not to try.

Modern Rechargeable Batteries

Nickel-Metal Hydride (NiMH), (Nickel-Cadmium (NiCd) - OBSOLETE), and Lithium Ion (Li-Ion)

When this article was first written in 2011 the commonest general purpose rechargeable batteries were Nickel-Cadmium (NiCd or NiCad) and the more modern, and higher performance, Nickel-Metal Hydride (NiMH). Lithium Ion (Li-Ion) batteries were already very common in cellphones, cameras, GPS receivers and similar portable electronic equipment but were not generally used as discrete batteries so I did not discuss them.

When any of these batteries are made into special battery packs for particular equipment (cameras, electric power tools, etc.), the equipment signals when the battery needs recharging, and the correct charger is supplied with the equipment. You do not usually need a DVM to work with such batteries.

But at that time NiCd and NiMH batteries also came as standard cylindrical batteries in the standard AA, AAA, C and D sizes, or even as multi-cell PP3 (or other) batteries. Today Li-Ion batteries are supplied in all these formats (and the larger 18650 cylindrical cell) and also in rectangular battery packs of many different sizes, while NiCd batteries are only found in older equipment and are mostly unavailable for sale (cadmium is toxic). Your DVM can help you manage all of these.

NiMH (& NiCd) Rechargeable Batteries

The difference between NiMH (and NiCd, but, as we have mentioned, these are becoming obsolete) and rechargeable and non-rechargeable alkaline batteries is that the NiMH (& NiCd) voltage, when fully charged, is about 1.25 volts, not 1.5, and their discharged voltage is 1.0 volts. Much modern electrical and electronic equipment is designed to work well with these batteries (and, usually, also with alkaline ones) and does not stop working until the voltage drops to about 1.0 volts per cell. (PP3 batteries made with NiCd or NiMH technology may have a working voltage of 7.2 volts rather than 9 volts, but some have a working voltage of 8.4 volts - read the label!)

Unlike alkaline cells, the NiMH (or NiCd) cell voltage does not drop much during discharge until the battery is nearly spent, when it drops quite quickly. The voltmeter, therefore, can tell you that a NiMH (or NiCd) battery is OK (1.2-1.25 volts per cell), or that it is discharged (about 1.0 volts per cell) but it is a poor guide to how much charge is remaining.

The simplest chargers for these batteries rely on the user knowing how long an exhausted battery must be charged, and if the battery is not fully discharged they may overcharge it, which will reduce its long-term life expectancy. Voltage measurements with a DVM are of little help in monitoring the state of charge.

The MAHA MH-C9000 Smart Charger

Smart chargers contain quite complex circuitry which measures cell temperature and rate of change of cell voltage and reliably stops charging at the right moment. It is well worthwhile investing in these more expensive chargers if you expect to make much use of rechargeable NiMH (or NiCd) batteries.

Li-Ion Rechargeable Batteries

Li-Ion cells have a nominal working voltage of 3.6 volts. This is much higher than alkaline or NiMH cells so, even if they are the same size, it is not possible to replace the older types with Li-Ion ones in existing equipment. (There are some LED torches/flashlights which are designed to work with either type of battery, but these are exceptional - never assume that Li-Ion and NiMH/alkaline batteries are interchangeable.)

When freshly charged the Li-Ion battery voltage is about 4.2 volts, and when fully discharged about 3 volts - it is roughly proportional to the state of charge so, unlike NiMH batteries, you can check the state of charge with your DVM on its 20 V range - if the voltage is above 4 volts it is fully charged and if it below 3.2 volts it is nearly discharged. To measure this voltage on cylindrical cells or any cells with just two terminals connect the DVM to the two terminals - polarity does not really matter in this case, if you connect the leads the wrong way round the meter will show a negative voltage but you are still reading the voltage you need to know. If you have a battery with three terminals, like many cellphone and camera batteries, connect the leads to the outside ones. If the reading is below 1 volt, try connecting between the centre and one or other of the outer ones. (The third terminal is usually a temperature sensor which is used to prevent too fast charging inside the phone/camera.)

All chargers for Li-Ion batteries contain circuitry to prevent overcharging, most of them check for overheating during charge as well, and nearly all of them indicate when the battery has been fully charged - so it is not necessary to worry about leaving Li-Ion batteries in the charger for too long a time.

The Foxnovo 4S Intelligent Charger

An "intelligent" charger for Li-Ion batteries is usually one which can tell the difference between NiMH and Li-Ion batteries - and can charge both safely!

Lead-acid batteries

Cars, motor-cycles and boats, and uninterruptible power supplies, use lead-acid rechargeable batteries. They usually have six cells and give 12 volts, but some small boats and bikes use 6 volts, and trucks and larger boats may use 24 volts. The voltages given in the rest of this section refer to 12 volt batteries and should be divided by 2 for 6 volt ones, or multiplied by 2 for 24 volts.

A fully-charged lead acid battery has a voltage of 12.6 volts if measured without any current flowing (immediately after charging it may be as high as 13.4 volts, but unused it drops over a few hours to 12.6 V). As the battery discharges the voltage drops, fairly linearly, to about 11.4 volts at 10% remaining charge, so the unloaded battery voltage , measured with the DVM, is a good measure of the state of charge.

Batteries for cars and motor-cycles are normally kept near maximum charge and are expected to deliver large peak currents for starting the engine. Batteries in boats, motor homes and uninterruptible power supplies may be discharged very deeply - the batteries used for these different applications are different. Car batteries may be damaged by repeated deep discharges, while deep discharge batteries have lower maximum current.

Simple car battery chargers deliver a constant current of a few amps when the battery voltage is below about 13 volts, but above this apply a constant voltage of 13.4 volts (and some current limiting). It is possible to use the DVM on its voltage and 10 A current ranges to measure charge current and battery voltage. (If the DVM is connected across the battery when it is set to its 10 A current range rather than its 20 V voltage range it will draw a very large current from the battery and may be damaged or even catch fire - do not do this!)

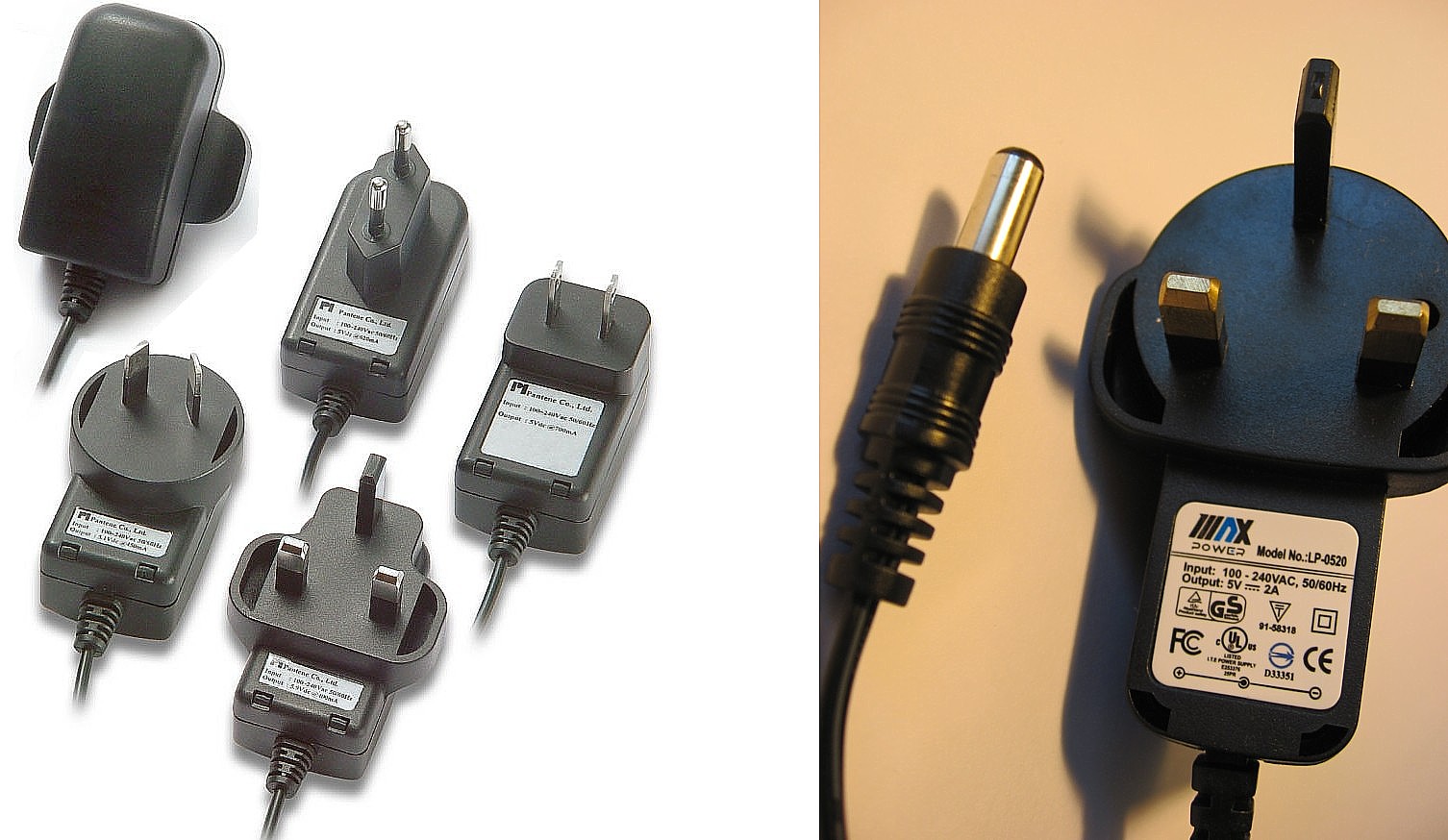

Small Mains Power Supplies ("Wall Warts")

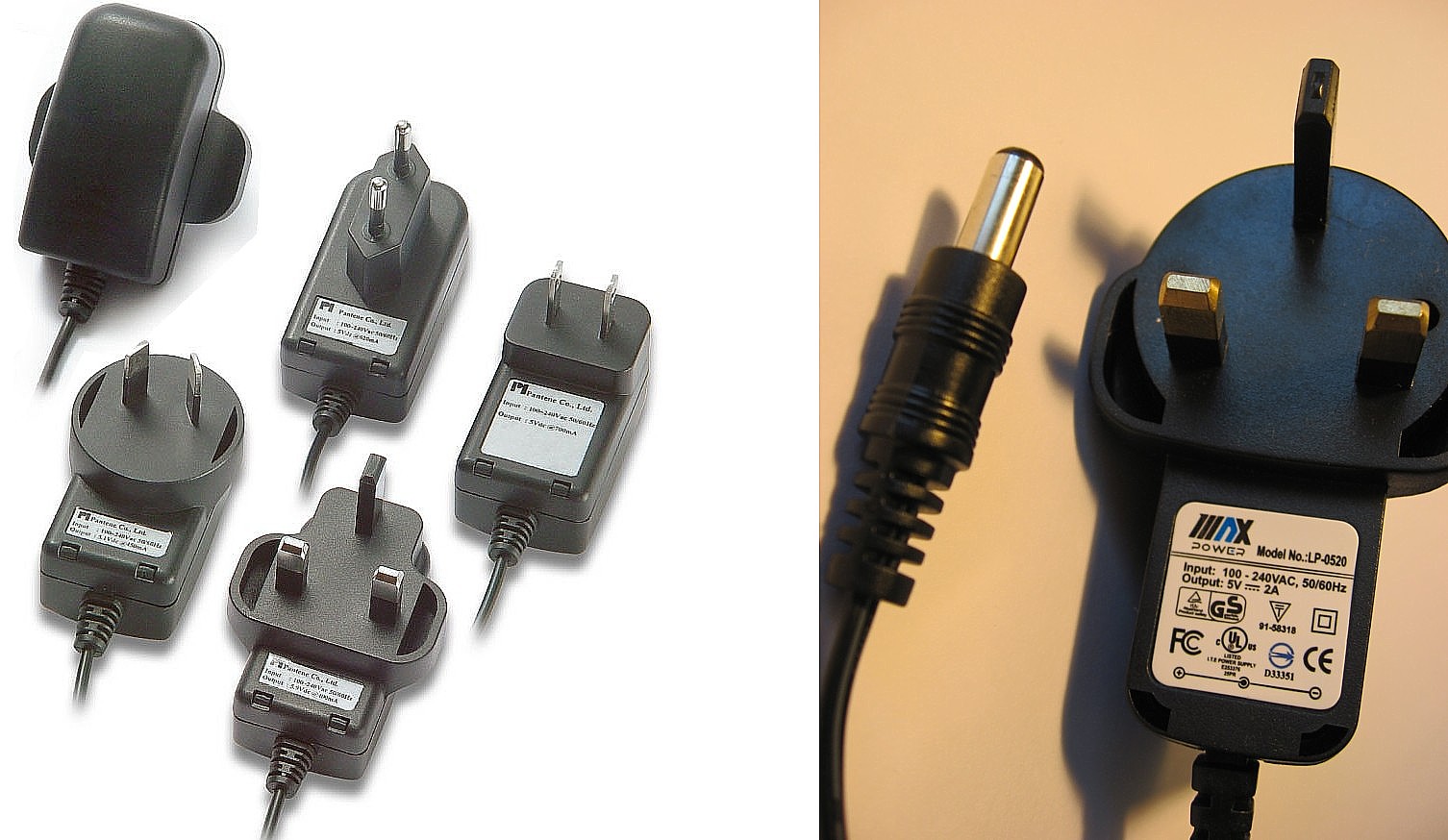

Many electronic devices today draw their power from small power supplies (sometimes called "wall warts") which plug into the mains and deliver low voltage (usually DC, occasionally AC) to the device.

It is possible to use your DVM to check if they are functioning correctly. Check the label for the rated output and whether it is AC or DC. This will have the format: OUTPUT: 5 V DC 2 A or OUTPUT: 9.5 V AC 250 mA where the 5 V or the 9.5 V is the voltage, DC or AC is direct current or alternating current, and 2 A or 250 mA is the maximum current rating. Sometimes AC will be replaced by the symbol ~ or DC by the symbols

or

or

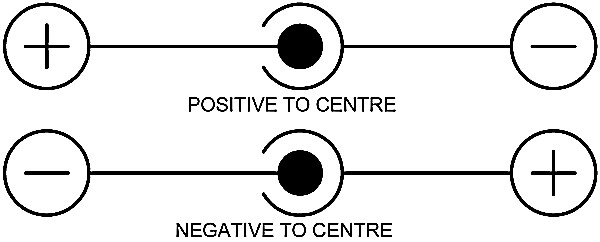

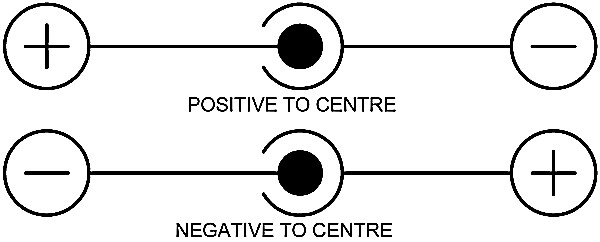

The polarity of DC supplies may be indicated by one of these symbols:

If it is a DC supply use the 20 V DC range (unless the voltage is over 20 V - in that case use the 200 V DC range), if it is an AC supply use the 200 V AC range. Plug in the supply and connect the test leads to the outer and inner of the plug on the supply (you may need to use a bent paperclip to access the inner connection - do not short circuit the supply). You can then check that the supply is delivering the correct voltage (if there is no load it may be up to 25% high).

Conclusion

A digital voltmeter is an invaluable domestic tool, enabling someone without any technical training to detect and correct problems with fuses, traditional incandescent light bulbs (both mains and low voltage torch [flashlight] and vehicle bulbs), batteries of all kinds and wall-warts.

In the hands of an experienced engineer there are many other jobs it can perform (the 830B can measure the gain of transistors), but these are beyond the scope of this note.

James Bryant

Hillhead Cottage

Calshot SO45 1BR

England

james@jbryant.eu

January 2011

(Edited - [1] added Li-Ion Battery details - October 2015 - [2] minor edits to introduction, battery and fuse sections - April 2017)

Visits since 2014-10-21